On the 19th, the Shanghai Municipal Commission of Economy and Information Technology, the Shanghai Municipal Commission of Development and Reform, and the Shanghai State owned Assets Supervision and Administration Commission released the "Implementation Plan for Accelerating the Development of 'AI+Manufacturing' in Shanghai". Among them, it is proposed to implement the "Mold Shanghai · AI+Manufacturing" action, promote the deep integration of artificial intelligence technology and manufacturing industry, accelerate the empowerment of new industrialization, and form new quality productivity. Through three years of hard work, the level of intelligent development in the manufacturing industry in this city has been further improved, and a number of innovative achievements have been formed in the fields of corpus, models, platforms, scenarios, etc.

Attached

Implementation Plan for Accelerating the Development of "AI+Manufacturing" in Shanghai

In order to thoroughly implement the national strategic deployment of promoting artificial intelligence to empower new industrialization, implement the Shanghai "Model City" project, and accelerate the development of intelligent manufacturing, this implementation plan is formulated.

1、 Main objectives

Implement the "Mold Shanghai · AI+Manufacturing" action, promote the deep integration of artificial intelligence technology and manufacturing industry, accelerate the empowerment of new industrialization, and form new quality productivity. Through three years of hard work, the level of intelligent development in the manufacturing industry in this city has been further improved, and a number of innovative achievements have been formed in the fields of corpus, models, platforms, scenarios, etc. Promote the intelligent application of 3000 manufacturing enterprises; Create 10 industry benchmark models and create 100 benchmark intelligent products; Promote 100 demonstration application scenarios and build around 10 "AI+Manufacturing" demonstration factories; Develop around 5 comprehensive integrated service providers, cultivate a group of competitive professional service providers, and accelerate the formation of an intelligent manufacturing development ecosystem.

2、 Tackling basic and cutting-edge technologies

(1) Enhance the foundational capabilities of industrial models

Promote the innovation of multimodal algorithms for basic models, strengthen the understanding of physical laws such as fluid, electromagnetic, and vacuum, and enhance physical simulation capabilities; Strengthen the recognition of industrial drawings, operation manuals, product defects and other information, and enhance visual processing capabilities; Strengthen the understanding of temporal data and process constraint rules, and enhance intelligent decision-making capabilities. Strengthen the industrial reasoning ability of basic models, streamline industrial standard operating procedures, gather a batch of prompt words, and promote intelligent agents to understand industrial tasks, instructions, and roles; Targeting generalized scenarios in the manufacturing industry, we use methods such as knowledge distillation and logical scoring to create a batch of inference datasets that support fine-tuning of industrial models.

(2) Breakthrough in cutting-edge technologies of industrial intelligence

Develop industrial metaverse, build industrial basic model library and information library, tackle spatial computing technology, achieve digital mapping and virtual real collaboration of all spatial elements such as factories, warehouses, laboratories, etc., support application innovation such as factory layout optimization and automatic guided vehicle routing. Explore the "cloud edge end" model system, develop intelligent edge devices such as virtual programmable logic controllers (PLCs) and distributed control systems (DCS), promote model miniaturization and edge deployment, and enhance the rapid response capability of edge side intelligent applications. Develop industrial tool interoperability protocols, benchmark model context protocols and intelligent agent open protocols, and develop industrial universal protocols and interfaces for intelligent agent tool invocation.

(3) Developing industrial data governance and synthesis technology

Develop industrial data governance technology, develop a "sampling, washing, and mapping" toolchain for unstructured and semi-structured data in the industrial field, develop data standardization governance technologies such as industrial data feature extraction and process retrieval enhancement generation, build an industrial symbol semantic standardization library, promote the formation of industry data dictionaries and digital mainlines, and support unified modeling and association fusion of multi-source data. Develop industrial data synthesis technology, carry out data synthesis pilot projects for complex environment equipment operation, assembly operations, operation and maintenance management, and support model training and application verification for simulation, industrial robot generalization and grasping.

3、 Building a key element platform

(4) Building an industrial intelligent computing cloud platform

Promote the upgrading of industrial cloud enterprises to create intelligent computing clouds, tackle low latency distributed inference architectures, factory level computing power scheduling and other technologies, develop tool modules for corpus processing, model training, model management, intelligent agent development, etc., provide services such as "corpus package", "computing power package", "model package", etc., form various deployment solutions such as cloudification, localization, miniaturization, and lightweighting, and support the transformation and upgrading of large, medium and small enterprises. Promote professional service providers to connect with industrial intelligent computing cloud, iteratively develop intelligent tools and agents for vertical industries, and gradually form Model as a Service (MaaS) capabilities.

(5) Building a public service platform for industrial language materials

Promote the joint creation of an industrial corpus public service platform by corpus enterprises, manufacturing enterprises, service providers, etc., and build high-quality multimodal corpora for industries such as ships, aviation, automobiles, energy, and steel, forming industrial strategic corpora as well as model fine-tuning data, strong inference data, evaluation corpora, entity knowledge graphs, scarce scenario corpora and other industrial professional corpus resources. Explore diverse benefit sharing and incentive mechanisms such as embedded points to promote efficient aggregation and sharing of language materials. Promote the chain owner enterprise to create an industrial data space based on the upstream and downstream needs of the industry, and achieve the aggregation of same industry corpus and cross industry corpus sharing. Guide small and medium-sized enterprises to enhance their data governance capabilities, establish internal knowledge bases, apply knowledge graphs, retrieval enhanced generation (RAG) and other technologies, and quickly apply models on the scene side.

(6) Building an integrated innovation base

Give full play to the leading and driving role of high-quality enterprises, build an "AI+Manufacturing" integrated innovation base, connect with intelligent computing cloud, corpus and other platforms, tackle common industry technologies such as model engineering, intelligent agent engineering, and application development tools, and create demonstration application scenarios. Promote the service capabilities of vertical corpora, intelligent products, and scenario applications in the base construction industry, carry out application training, standard setting, and technology platform construction, and promote the overall level of intelligence in the industry.

4、 Promote the application of key industries

(7) Accelerate the empowerment of key industries

Focusing on industries such as integrated circuits, electronic information, automobiles, high-end equipment, shipbuilding and marine engineering, aerospace, advanced materials, steel, fashion consumer goods, and pharmaceutical manufacturing, we aim to promote innovative application of artificial intelligence technology in enterprises, create segmented industry models, develop specialized small models for specific scenarios, build a multi-level industrial model system, improve the collaborative efficiency of large and small models, and accelerate their practical application in industrial scenarios.

Column Application of "AI+Manufacturing" in Key Industries

Integrated circuits: Promote electronic automation design (EDA) enterprises to build intelligent design capabilities, shorten design cycles, and improve chip performance. Promote the application of artificial intelligence technology in scenarios such as computational lithography, auxiliary defect detection, and process development, focusing on chip manufacturing, packaging, and other aspects, to improve yield and production efficiency.

Electronic Information: Targeting scenarios such as multi specification box type mixing, material picking, and precision operations, pilot AI+robot applications will be launched to promote the large-scale implementation of technologies such as machine vision, intelligent scheduling, and supply chain brain. Support electronic information enterprises to accelerate their intelligent transformation and build or upgrade automated production lines.

Automobile: Promote the construction of an intelligent research and development system for vehicle and component enterprises, covering computing power support, data collection, model training, and simulation testing, to achieve a data-driven intelligent automotive development paradigm. Build an industrial brain system, deepen the application of quality judgment, supply chain management, defect detection, etc., and gradually achieve intelligent management of the entire process.

High end equipment: Promote the development of intelligent agent applications in high-end equipment enterprises, enhance the intelligence level of research and development design, production and manufacturing, and reconstruct human-computer interaction methods. Promote instrument and meter enterprises to build multimodal models for mass spectrometry, spectroscopy, chromatography and other scenarios, and achieve functions such as instrument parameter self-tuning and fault warning.

Marine Engineering: Develop intelligent ship design software, based on historical ship type databases and real-time simulation data, to achieve functions such as line type scheme generation and structural design optimization. Monitor the entire process of key processes such as cutting, welding, transportation, and pre-processing to achieve quality management and fault diagnosis based on digital models.

Aerospace: Promote the intelligent assembly and manufacturing of large aircraft, and create applications such as special process control, intelligent detection of overall dimensions, intelligent scheduling, and flexible intelligent production lines with multi robot collaboration. Promote the construction of satellite intelligent factories and develop intelligent detection equipment for products such as satellites and rockets.

Advanced Materials: Build an AI powered materials center to cultivate four types of small models: advanced alloys, special polymers, inorganic materials, and organic compounds. Promote the construction of an electronic material gene bank. Establish a bio intelligent development and manufacturing system to empower the development of bacterial strains and key enzymes, metabolic pathway design, and reaction process control.

Steel: Building a high-quality corpus of steel, creating a multimodal large model for the steel industry, and tackling the multimodal capabilities of models in prediction, decision-making, control, and other aspects. Develop intelligent agents such as batching furnace managers, planners, quality inspectors, and safety officers to achieve integrated pre iron batching, intelligent diagnosis and adjustment of blast furnace conditions, and other applications.

Fashion consumer goods: Promote the application of models in light industry, food and other fields to understand demand trends, build a production and manufacturing system that dynamically adjusts with sales, and achieve flexible manufacturing and integrated production, supply and marketing. Accelerate the integration of creative design and artificial intelligence, and promote the intelligent research and development of product appearance, formula, and other aspects.

Pharmaceutical manufacturing: Build an intelligent drug research and development platform, carry out technological breakthroughs such as intelligent screening of drug targets, optimization of molecular structure design, and crystal form prediction. Build a flexible production line and supply chain collaboration system to enhance the quality control and full process traceability capabilities of drug production.

(8) Create common demonstration scenarios

Organize a scenario map around the entire manufacturing process to support enterprises in exploring high-value application scenarios. Develop, design, and construct smart laboratories, virtual simulation design, generative design, and other scenarios to create new design patterns. The construction of high-precision, full process simulation intelligent virtual pilot test and other scenarios through pilot testing has been proven to shorten the pilot test time and reduce process costs. Intelligent flexible assembly, non-destructive intelligent defect detection, production adaptive adjustment and other scenarios are constructed in production and manufacturing to improve manufacturing accuracy and efficiency. Build dynamic scheduling, flexible supply chain, inventory optimization and other scenarios for supply chain management to enhance supply chain collaboration efficiency. Business management and service construction are based on intelligent agent based business decision analysis, intelligent carbon emission management, digital human marketing, intelligent operation and maintenance management, and other scenarios to improve business efficiency.

(9) Exploring cutting-edge manufacturing models

Promote manufacturing enterprises to establish themselves on the basis of full process intelligence, explore new manufacturing models such as software defined factories, fully on-demand manufacturing, and intelligent factory networks. Using the "industrial brain" as the decision-making center, intelligent optimization of design, development, and mass production is achieved, combined with large-scale human-machine collaboration and equipment module combination, to achieve large-scale flexible manufacturing. Relying on the industrial metaverse to achieve integrated design and manufacturing, dynamically configuring factory resources, adaptively reconstructing production processes based on demand, and achieving efficient production of customized products. Relying on the platform to connect factories within the industrial cluster, demand driven product digital design simulation and supply chain service optimization.

(10) Building an "AI+Manufacturing" Factory

Promote the construction of "AI+Manufacturing" demonstration factories characterized by high-density distribution of intelligent agents and multi scenario integration, comprehensively apply spatial computing, multi-agent collaboration and other technologies, gather various scenario models, intelligent products and equipment, promote the practical deployment of multi type embodied intelligence represented by humanoid robots in typical scenarios, connect various industrial software systems, enhance dynamic perception capabilities, reflect new manufacturing models such as software defined factories, fully on-demand manufacturing, and intelligent factory networks, and form a benchmark demonstration role.

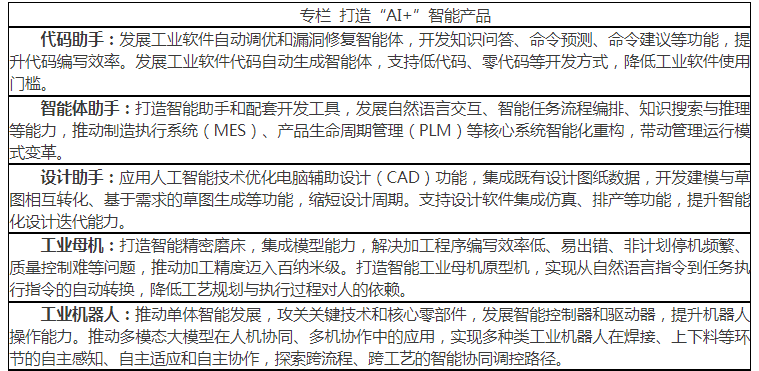

5、 Building "AI+" intelligent products

(11) AI+Industrial Software Tools

Based on the production capacity of large model code and text, develop automatic optimization and vulnerability repair functions for industrial software, and explore model-based low code and zero code application development models. Promote the reconstruction of production execution systems, product lifecycle management systems, and other software based on artificial intelligence, support the improvement of production efficiency, and transform production management models. Promote the integration of physical law simulation, high-throughput computing and other functions into R&D and design software, and achieve the generation of new designs based on historical data.

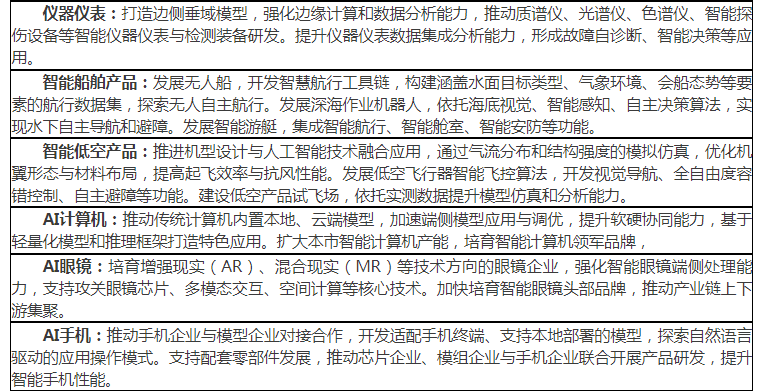

(12) AI+Industrial Products and Equipment

Promote the integration and application of artificial intelligence technology in industrial mother machines, industrial robots, instruments and meters, energy equipment, medical equipment, ships, and low altitude industrial products and equipment, achieve intelligent upgrading and functional expansion, and comprehensively enhance the level of perception, interaction, control, collaboration, and autonomous decision-making. Focusing on large models and edge intelligence applications, enhancing the adaptability, flexibility, and operational efficiency of equipment systems. Support high-quality enterprises to create an intelligent product matrix based on existing industrial products and equipment.

(13) AI+consumer terminal

Promote cooperation between consumer terminal enterprises and artificial intelligence enterprises to develop end-to-end models, carry out cloud based model end-to-end deployment, enhance the model application capabilities of terminals, and promote innovation in intelligent terminal operations. Promote the iterative upgrading of new intelligent consumer terminals such as AI computers, AI glasses, and AI smartphones, accelerate the guidance of upstream and downstream enterprises in the industrial chain, and promote the development of intelligent terminal industry clusters.

6、 Actively creating a development ecosystem

(14) Cultivate professional service providers

Promote digital transformation, upgrade industrial Internet service providers to intelligent service providers, and provide intelligent products and solutions. Establish service provider certification standards, focus on selecting and cultivating a group of professional service providers such as industrial corpus data, intelligent computing cloud, model platform, intelligent agent development and application, embodied intelligence, etc., support the development and growth of comprehensive integrated service providers, provide characteristic service packages for specific industries and scenarios, and form a "clustered" service system.

(15) Promote the intelligent upgrade of the platform

Promote the industrial Internet platform to integrate artificial intelligence technology, give play to the platform's accumulated industrial scene, equipment, production line and other data advantages, develop models, tools and agent applications focusing on vertical industries, and enhance the model as a service (MaaS) capability. Promote the industrial Internet platform to combine with the big model, develop intelligent functions such as engineering drawing analysis, order matching, factory recommendation, automatic quotation, and image search, strengthen the accurate connection and efficient collaboration of upstream and downstream resources, and promote the intelligent transformation of the supply chain.

(16) Accelerate the application of robots

Support the deployment of industrial robots in key industries such as electronic information, automotive, and equipment for work scenarios with high repeatability, danger, and health hazards, to improve production efficiency and safety. Promote the large-scale application of intelligent robots in assembly, welding, spraying, material handling and other processes. Promote the construction of human-machine collaborative intelligent manufacturing operation units in industries such as steel and shipbuilding, and achieve unmanned operation of complex processes. Develop safety and reliability testing methods for humanoid robots in industrial scenarios, and promote the certification of products.

(17) Strengthen scene guidance

Targeting generalized scenarios such as research and development design, pilot testing, production and manufacturing, supply chain management, and business management and services, select a batch of typical cases of "AI+manufacturing", develop scenario construction guidelines, and form a "one scenario, one guideline" approach. Promote standardization of model selection, corpus preparation requirements, intelligent agent capability requirements, training fine-tuning time, inference computing power requirements, stability situation, management application requirements, etc., guide enterprises to better choose scenarios and allocate resources, reduce trial and error costs, and promote large-scale promotion.

(18) Cultivate professional talents

Implement the "AI+Manufacturing" Talent Pioneer Training Program, relying on universities, research institutes, enterprises, and talent training bases, to accelerate the cultivation of composite talents who are familiar with manufacturing mechanisms and master artificial intelligence skills. Deepen the integration of industry and education, promote the acceleration of artificial intelligence+new engineering construction in universities, and promote the "order based" and "relay based" training models between schools and enterprises. Establish a comprehensive training curriculum system and textbook resources that cover multiple levels of talent, increase digital training for industrial workers and skilled personnel, and enhance the innovation awareness and application ability of enterprise personnel in artificial intelligence.

(19) Promote the integration of production and finance

Guide banks and other financial institutions to develop exclusive financial products and services for digital and intelligent transformation enterprises, optimize loan procedures and approval processes for high-quality enterprises, and increase credit support. Support service providers with intelligent transformation platforms, system integration, and other functions to meet the financing needs of enterprises through supply chain finance and other means. Explore to use enterprise production data connected to industrial Internet and other platforms as credit enhancement items for bank loans. Support service providers and other enterprises to pledge their intellectual property and patented technologies for financing. Encourage leasing companies to provide specialized leasing services for smart products and equipment. Utilize the role of the municipal policy based financing guarantee fund to provide financing guarantee services to eligible enterprises. Promote the development of "AI+manufacturing" supported by urban related industry funds, social capital, etc., and accurately invest in projects and innovative entities such as corpus construction, model development, scenario application, and service providers.

(20) Improve standards and safety systems

We will increase the supply of basic commonalities, key technologies, and improve security governance standards around aspects such as corpus, models, platforms, intelligent agents, products, and applications. Strengthen industrial data corpus security, model algorithm security, system security, application security, etc., and create a secure and trustworthy foundation. Relying on third-party organizations to provide testing and verification services for models, intelligent agents, and embodied intelligence. Build a comprehensive intelligent evaluation framework and indicator system to scientifically evaluate the level of enterprise intelligence. Establish and improve intellectual property protection mechanisms to provide institutional guarantees for the innovative application of industrial intelligence.

7、 Strengthen the overall planning and promotion of work

(21) Promote the implementation of work tasks

Strengthen the overall organization and coordinated promotion of various tasks related to "AI+manufacturing", and implement key tasks, major projects, and important policies. Focus on key industries and develop a "one industry, one policy" promotion plan. Strengthen urban coordination, encourage key manufacturing areas with good industrial foundations and diverse scenarios to introduce "one district, one plan" and special policies, and build industrial intelligent industry clusters.

(22) Strengthen policy and financial support

Give full play to the guiding role of fiscal funds, increase support for intelligent technology transformation and application promotion, and support enterprise research and application of artificial intelligence technology through project construction subsidies, loan interest subsidies, and other means; Give full play to the roles of "model vouchers", "computing power vouchers", "corpus vouchers", etc., and provide proportional support for enterprise model procurement, computing power rental, corpus procurement and other service fees to reduce the cost of enterprise intelligent transformation.

(23) Promote open cooperation and exchange

Based on platforms such as the World Artificial Intelligence Conference and the China International Fair for Industry and Technology, we will strengthen cross industry and cross regional exchanges in the development of intelligent manufacturing, and deepen cooperation and sharing in areas such as policies, regulations, technical resources, and standards and specifications. Relying on the open-source ecosystem of artificial intelligence, improve public services such as manufacturing models, data, and toolchains. Promote the cross regional provision of technology and landing services by service providers, model developers, and application entities in this city.

(24) Actively creating a development atmosphere

Promote various manufacturing enterprises, artificial intelligence enterprises, service providers and other entities to strengthen docking, deepen technical exchanges and project cooperation, and encourage state-owned manufacturing enterprises to take the lead in playing a leading and exemplary role. Carry out "unveiling and leading" activities in the fields of technological breakthroughs, intelligent products, and scenario applications, select a batch of demonstration projects, typical products, and excellent cases, and accelerate the formation of a good atmosphere for the development of "AI+manufacturing" throughout the city.